Use Dtools' MIOT Plugin to Connect

Use the MIOT function in Kinco DTools software to connect to the M-IoT platform

Premise

- The user must have at least one Kinco

FUTURE/GREEN/MASSseries screen, and the screen must be connected to the Internet (Ethernet / WiFi / 4G network).The HMI model selected in this case is M2100E; - The user's computer has installed the software

Kinco DTools V4.2or above, and can use it normally; - The user already has an account with management rights for the

Kinco M-IoTplatform.

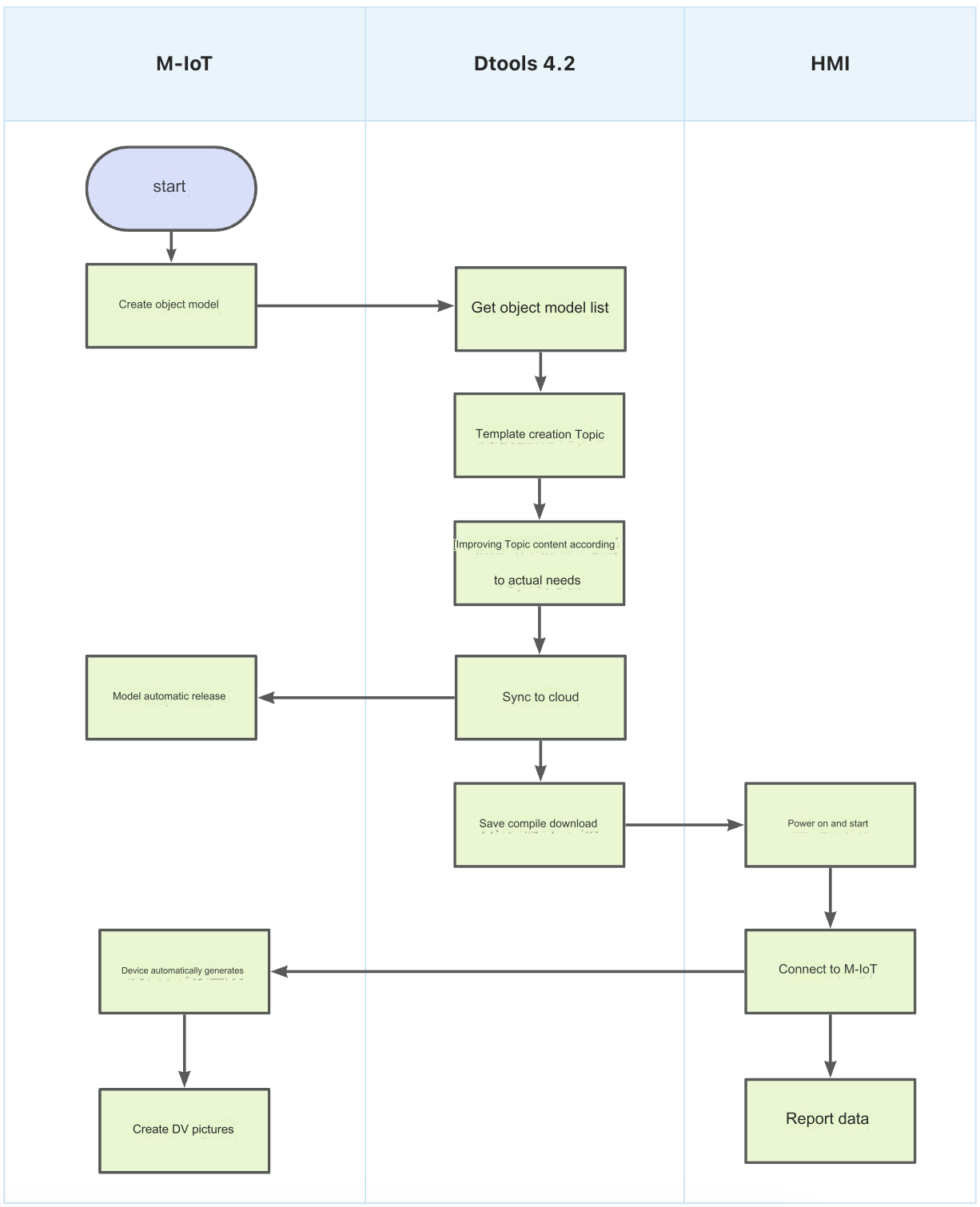

Config Flowchart

Steps

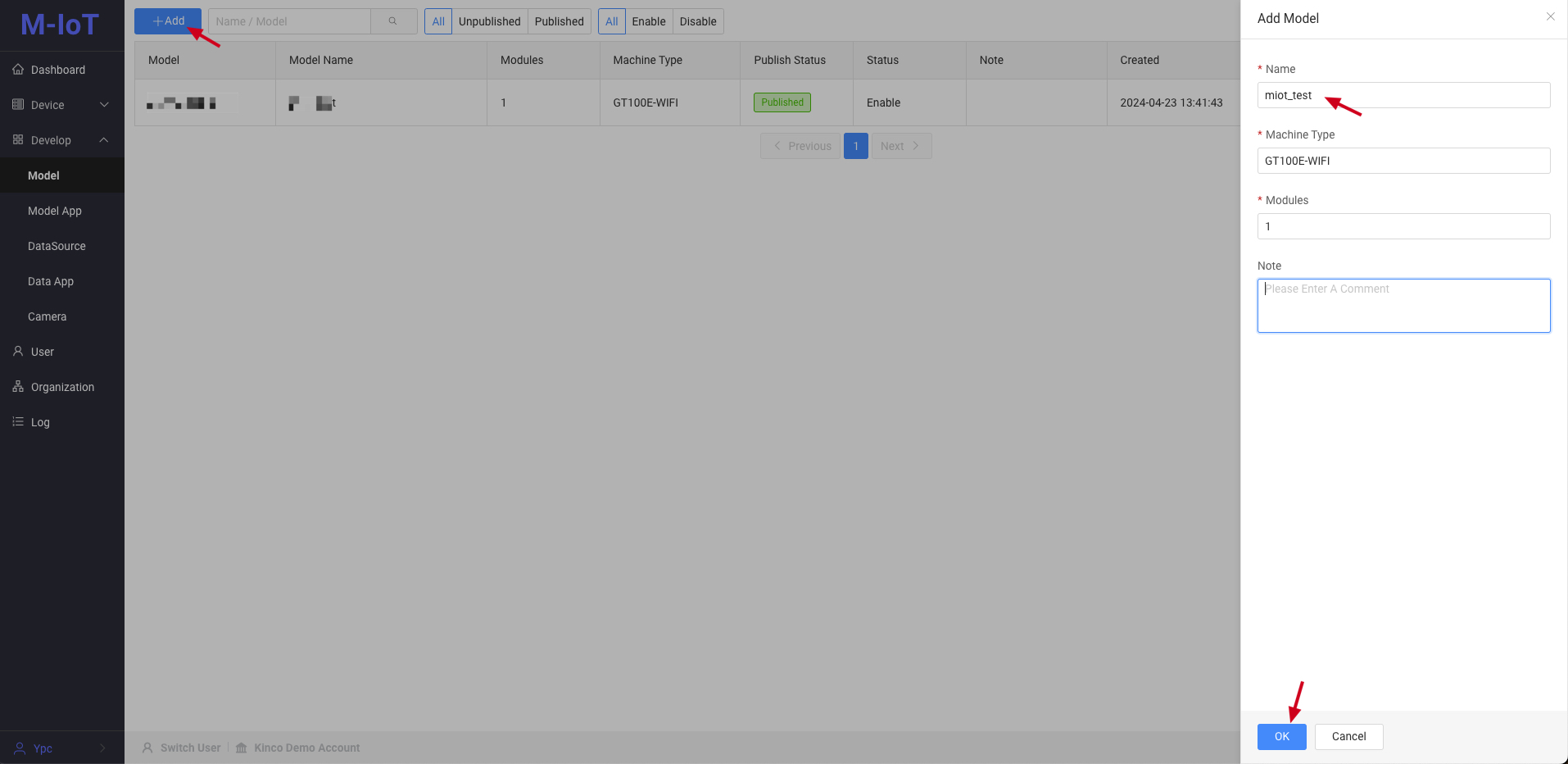

1. Create model

- Name, model:refers to device related information

- Number of modules:Here it refers to the number of acquisition terminals of a device.Generally, it is

1. If it is a large device, multiple acquisition terminals report the same device data, then this isthe number of acquisition terminals

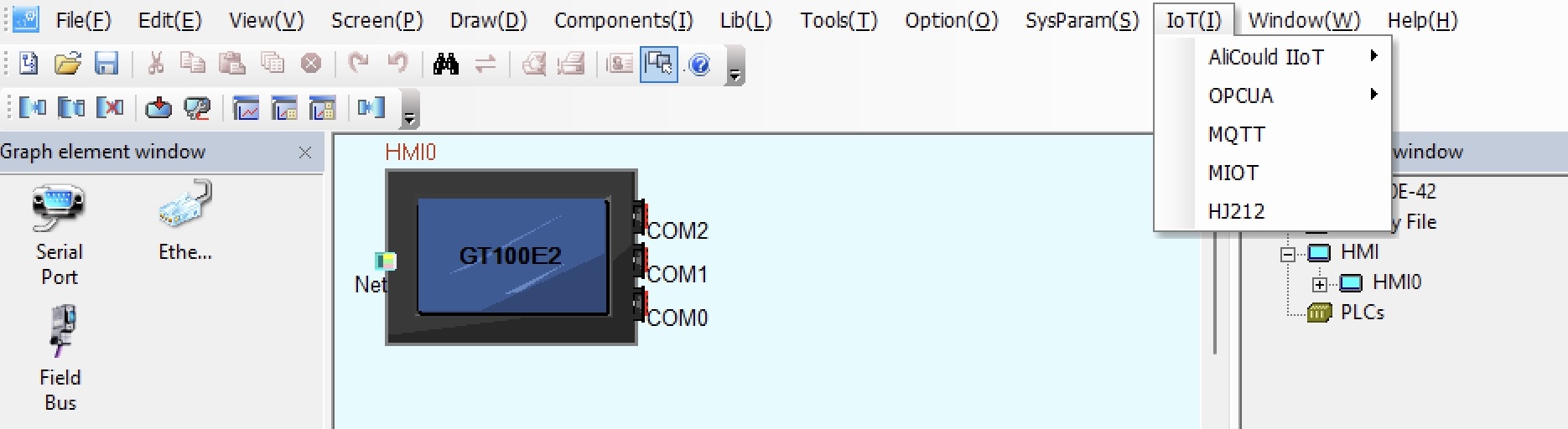

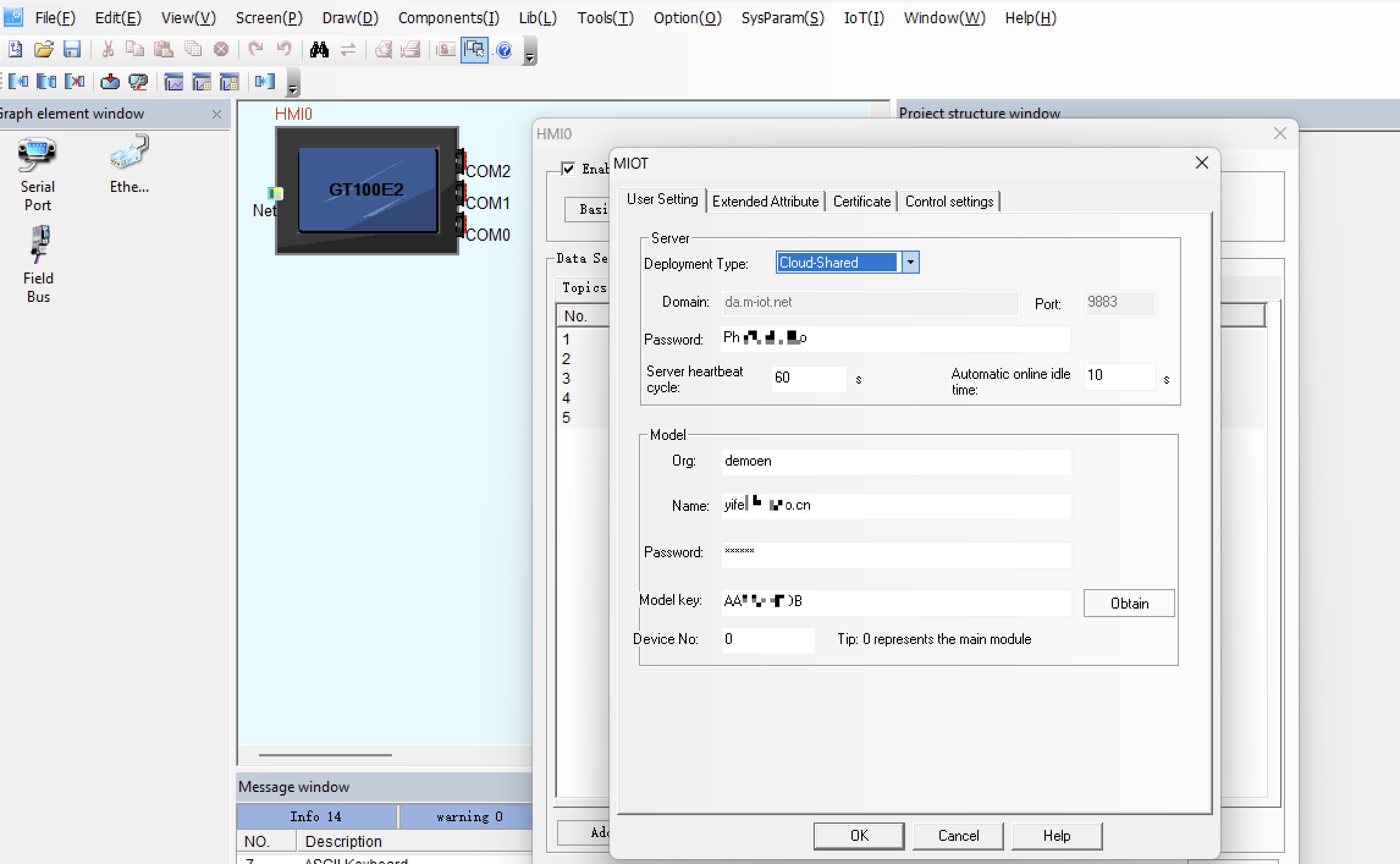

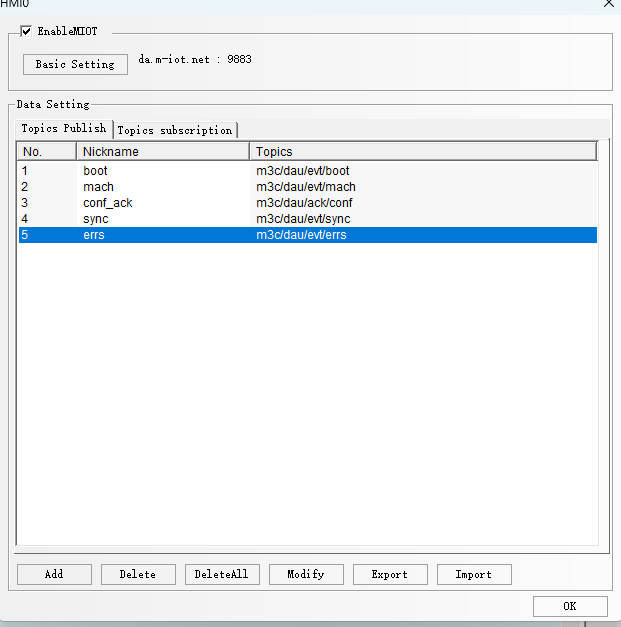

2. Dtools opens the MIOT module

After Dtools 4.2, in

the Internet of Things, the docking support ofMIOThas been added.

3. Basic Settings

- Server

- Deployment type:

Cloud deployment-shared - Domain name, port:

Default, no need to change - Password:

MQTT connection password(see the example below) - Heartbeat cycle, online idle time:

Default, no need to change

- Deployment type:

- Model

- Organization:

Organization Code(see the example below) - Username:

Username for log in the M-IoT platform(user email address) - Password:

Password for log in the M-IoT platform - Model:

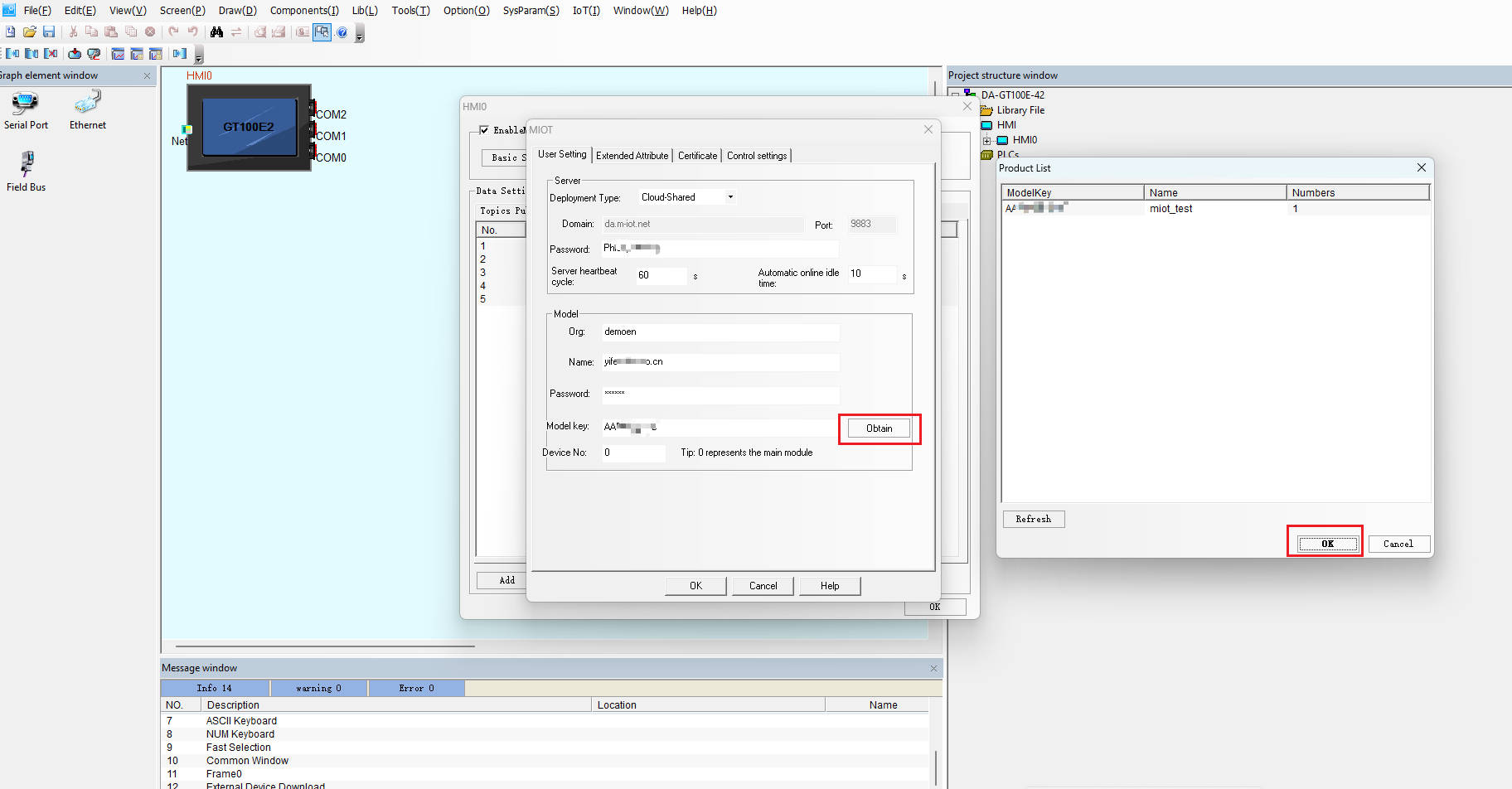

Select the model you created- Enter the correct

Organization Code,User NameandPassword, click theObtainbutton, and theModel Listwill pop up. - Choose the right model

- Enter the correct

- Device number:

0(only whencreating model, whenmodule numberis greater than1, it needs to be set according to the actual acquisition module number)

- Organization:

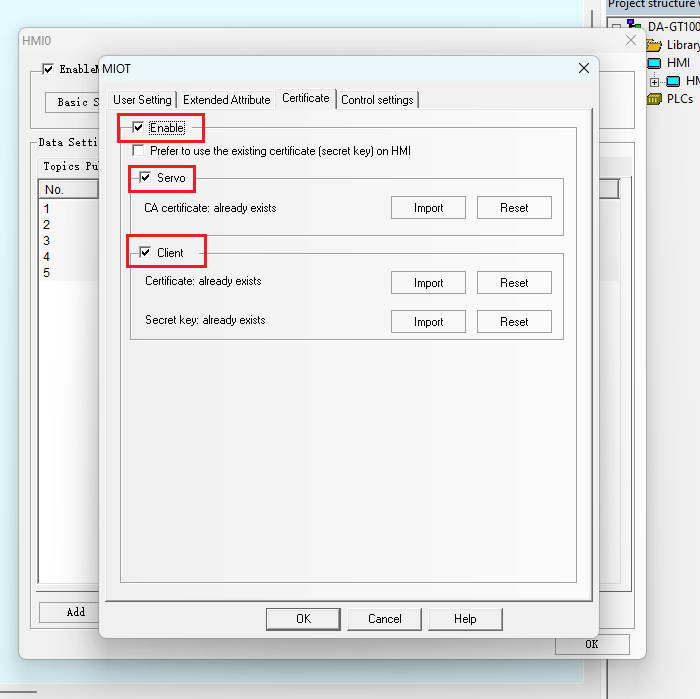

- Certificate authentication:The default is consistent with the legend

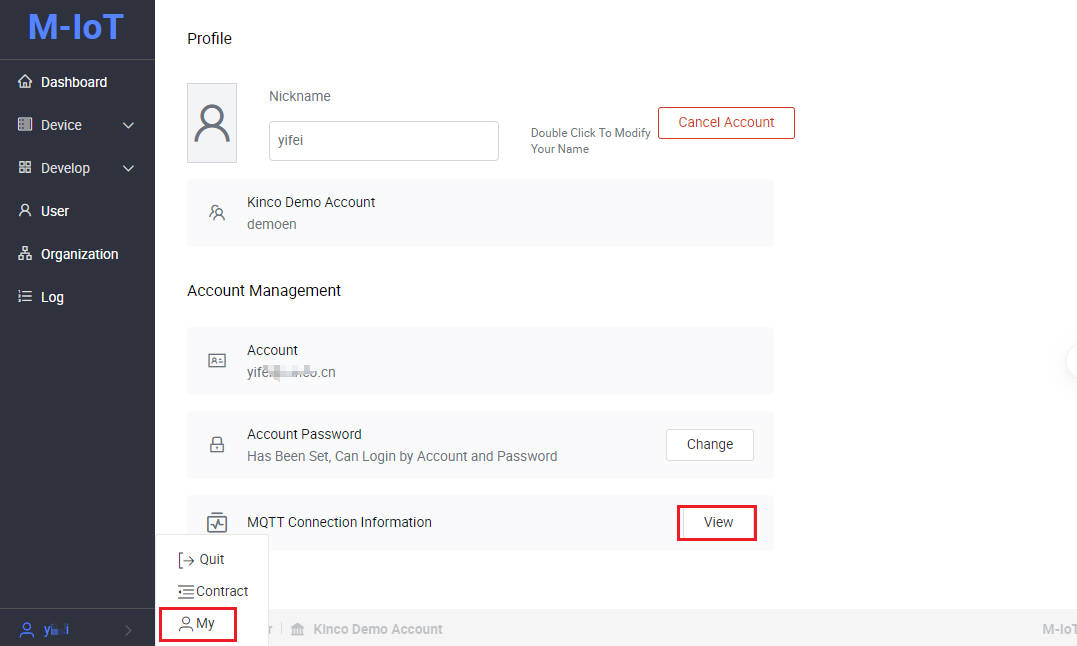

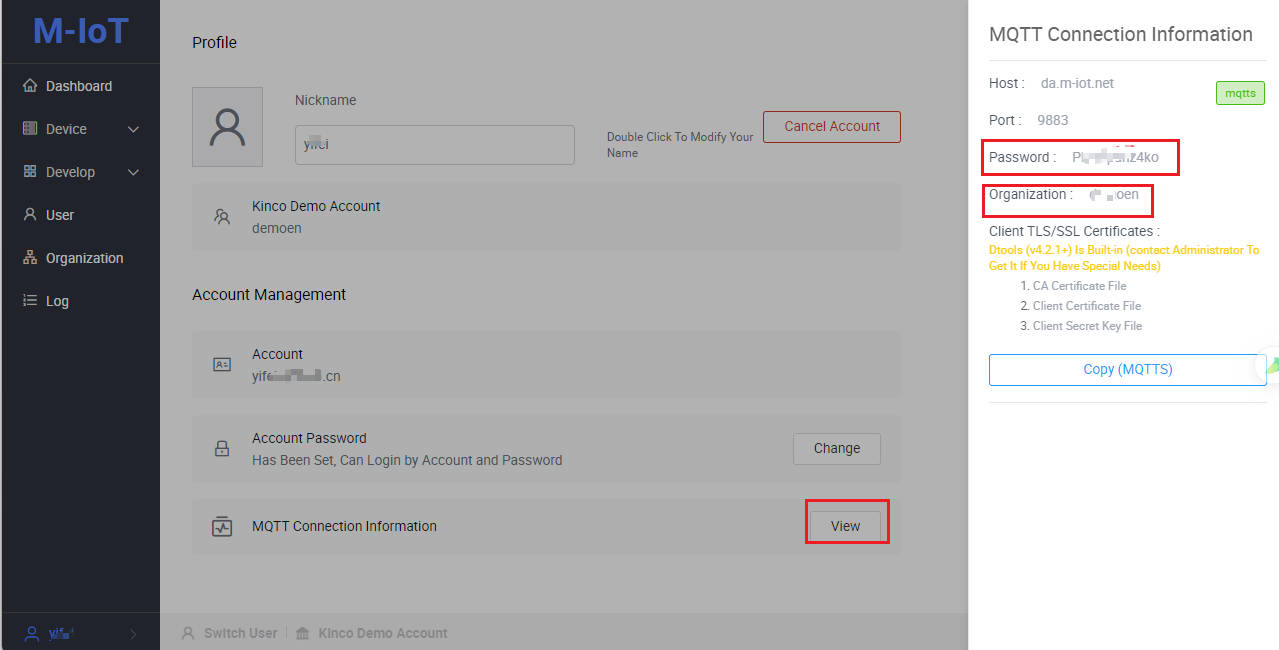

- Personal settings:After clicking on the

namein the lower left corner, the menuMywill appear- Open

MQTT connection information- Password:

MQTT connection password - Organization:

Organization code

- Password:

- Open

4. Create template

Click

Create Template, and inTopic Publish, 5 Topics are automatically generated, and inTopic Subscription, 1 Topic is automatically generated.

5. Topic publish config

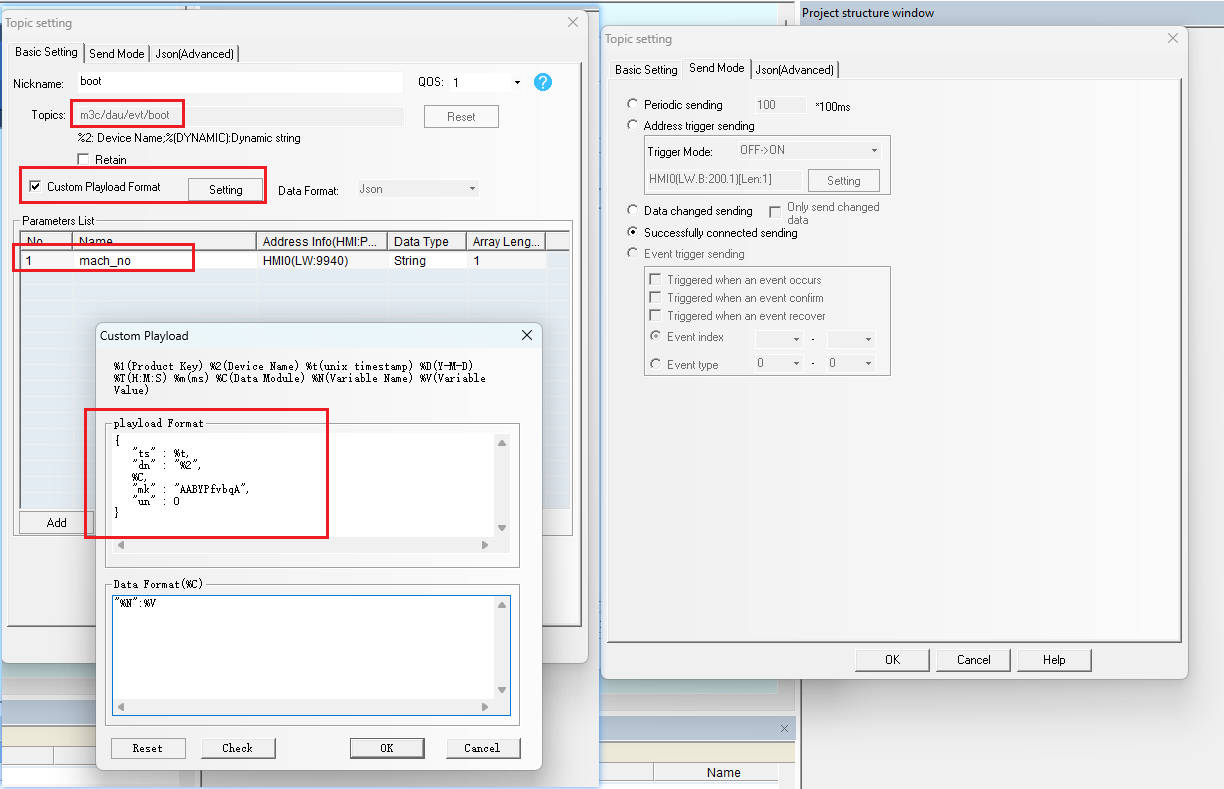

5.1 Topic:m3c/dau/evt/boot

- Device is ready (connect to MQTT successful)

- Device register to the platform + device online notify

- Parameters (fixed parameters)

dn:%2(%2 refers to the SN of the HMI)mk: model number (model number selected in miot basic settings)un: module number, usually0mach_no: device number ( The number of the actual device. If it is not empty, the platform will automatically generate the device!! )

Note:Since

%Cis used in the message, there must be content in the parameter list.Otherwise, during operation, the reported data will have format errors, resulting in errors.

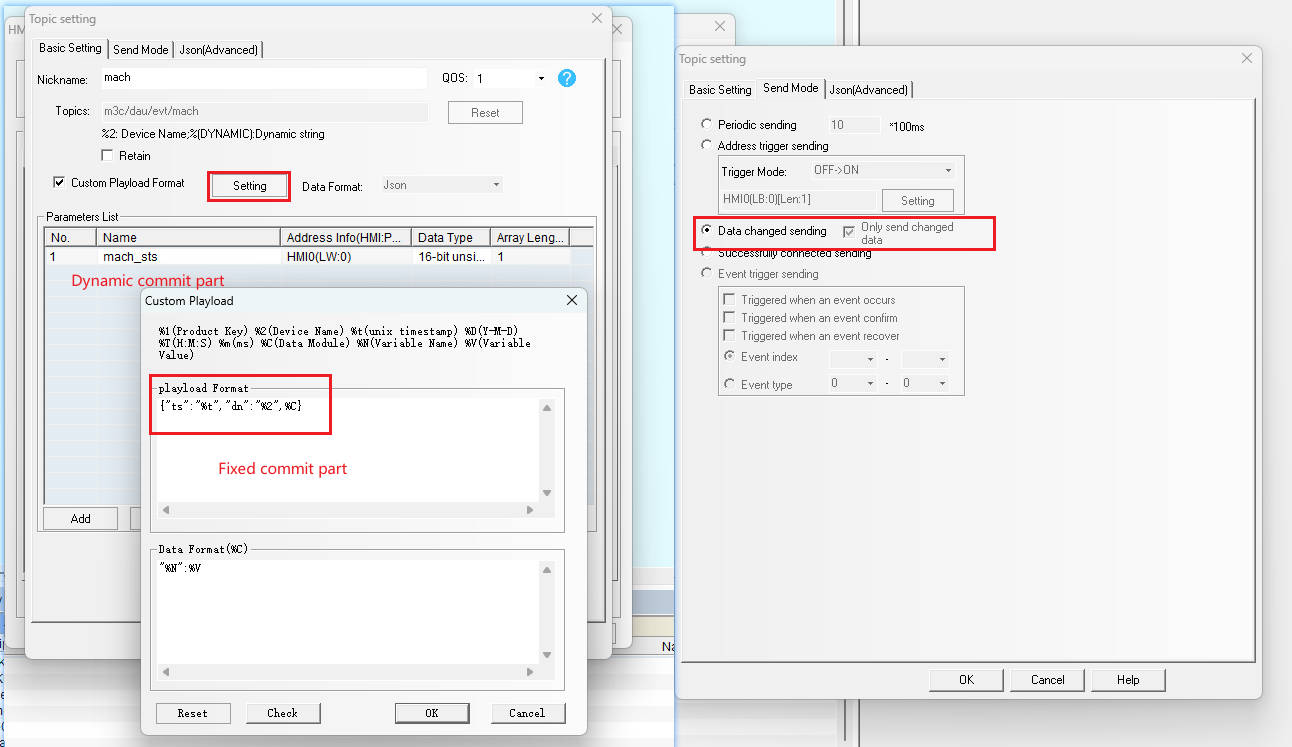

5.2 Topic:m3c/dau/evt/mach

- Environment parameter data submit

- Data change sensitive settings as environment parameters

- The settings for the instructions that need to be sent are environment parameters

- Send when data changes (only send changed data)

- parameter

dn:%2(%2 refers to the SN of the HMI)mach_sts:Fixed parameter, must exist.Indicates the operating status of the device- Parameter list contents

set_tandmach_stsare environment parameters that are sent when they are changed. When the parameters are changed, only the changed parameters are submitted

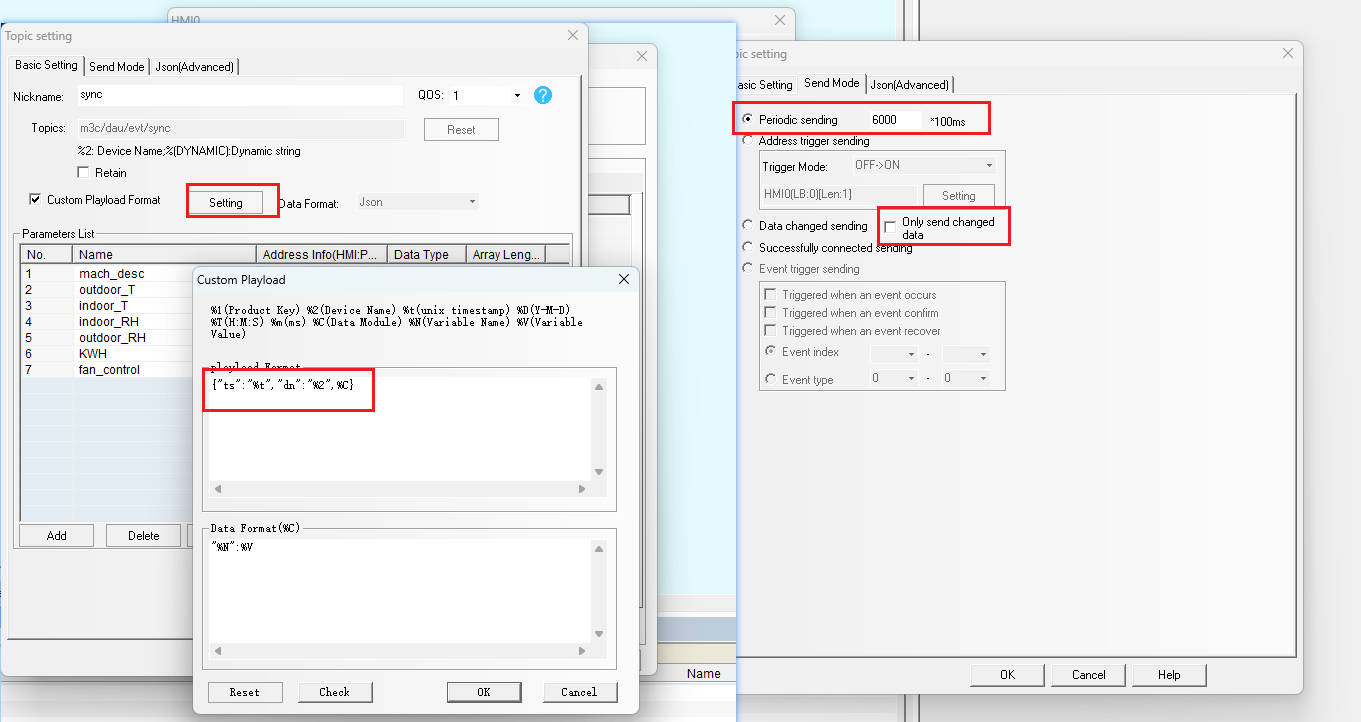

5.3 Topic:m3c/dau/evt/sync

- Run parameter data submit

- Monitoring data of device during running

- For data that is not sensitive to timeliness (production, running time, etc.)

- Periodic sending

- Recommended 6000 * 100ms = 10 minutes

- Send all data (do not check

Send only changed data)

- parameter

dn:%2(%2 refers to the SN of the HMI)- Parameter list contents

5.4 Topic:m3c/dau/evt/errs

- Fault occurs, device alarm

- Send when data changes (only send changed data)

- parameter

dn:%2(%2 refers to the SN of the HMI)- parameter list

- Parameter name convention:

err + 1 starts with a number - Bit Data

- Meaning of error written in description

- 0 means normal

- 1 means fault

- Parameter name convention:

5.5 Topic:m3c/dau/ack/conf

- Confirmation return message of sending parameters (return to tell the platform that the message has been received successfully)

- Address Trigger Send

- OFF -> ON (auto reset)

- When the data changes from

0to1, the data is sent, and after sending, the data changes back to0

- When the data changes from

- Address bit:In topic subscription, it is used to store the address bit of

req

- OFF -> ON (auto reset)

- Parameters (3 fixed)

dn:%2(%2 refers to the SN of the HMI)rid: parameter of the same name received in topic subscription (content sent by the platform is returned to the platform)- Same name

- Same address bits

- Same data type

cmd: the parameter with the same name received in the topic subscription (the content sent by the platform is returned to the platform)- Same name

- Same address bits

- Same data type

6. Topic subscription config

6.1 Subscribe to topic:m3c/das/cmd/conf/dau:%2

- Subscribe to the message content and specify the format of the received data

- Subscribe to data, and data distribution is initiated on the platform

- Receive parameters (3 fixed parameters + N environment parameters)

rid: the ID of the task being sent (needs to be returned to the original value in ack)- Used in ack return

cmd: the type of task being sent (needs to be returned in ack with the original value)- Used in ack return

req: fixed value1- The storage type is

bit, the default is0 - The platform sends a fixed value of

1. After the content is overwritten, OFF -> ON(0 -> 1), triggering the submission ofack. After the data is submitted, it resets to0 - As the trigger condition of ack

- The storage type is

- Environment parameters: The single content of the parameter with the same name is written and overwritten. The content of the environment parameters not send by the platform will not be written and overwritten.

7. Sync to the cloud

- After clicking the 'Cloud Sync' button, select 'Synchronize to MIOT', and the corresponding model data will be directly synchronized to the cloud.

- Sync to Cloud Error Analysis

- The device does not exist in the model

- Inspection items (general)

- mach_sts must be present in the

environment parametersofmodule 0 - Parameters are not allowed to end with

__diff - System reserved words:

iot_sts,ts,dn,req,rid,root,time,timestamp - Parameters can only be

environment parametersorrun parameters.(the two are mutually exclusive) - Only

environment parameterscan be sent

- mach_sts must be present in the

- Inspection items (general)

- The model has online device

- Check item

- The above general checks

- The same parameter does not allow type changes (number ←→ text)

- During development

- Delete all devices under this model

- Sync to the cloud again, force overwrite

- Officially running (need to keep the current device data)

- Add new parameters (e.g.:original parameters +

_01) - Synchronize again

- The original parameter data is retained and no longer reported.

- New parameters are reported normally

- Add new parameters (e.g.:original parameters +

- During development

- The device does not exist in the model